CNC Panel Saw

This automatic panel saw is used to precisely cut melamine faced panels, veneered wood-based materials and other panel materials with various sizes.

| Model | |||

| Overall size | 5300*5200*1750mm | 5900*5800*1750mm | 6400*6300*1800mm |

| Max. sawing length | 2600mm | 3300mm | 3800mm |

| Max. sawing thickness | 100mm | 100mm | 100mm |

| Max. sawing width | 2700mm | 3300mm | 3800mm |

| Positioning | Automatic | Automatic | Automatic |

| Sawing precision | ±0.1mm | ±0.1mm | ±0.1mm |

| Main saw motor power | 11KW (15KW optional) | 11KW (15KW optional) | 11KW (15KW optional) |

| Main saw blade outer dia. | 350-400mm | 350-400mm | 350-400mm |

| Main saw blade inner dia. | 80mm | 80mm | 80mm |

| Main saw rotation speed | 4100rpm/min | 4100rpm/min | 4100rpm/min |

| Scoring saw motor power | 2.2KW | 2.2KW | 2.2KW |

| Scoring saw blade outer dia. | 180mm | 180mm | 180mm |

| Scoring saw blade inner dia. | 55mm | 55mm | 55mm |

| Scoring saw rotation speed | 6100rpm/min | 6100rpm/min | 6100rpm/min |

| Saw carriage drive motor power | 1.5KW | 1.5KW | 1.5KW |

| Manipulator servo motor power | 1.5KW | 1.5KW | 1.5KW |

| Working air pressure | 0.6-0.8mpa | 0.6-0.8mpa | 0.6-0.8mpa |

| Material feeding speed | 0-80 M/min | 0-80 M/min | 0-80 M/min |

| Cutting speed | 0-100 M/min | 0-100 M/min | 0-100 M/min |

| Backward speed | 0-120 M/min | 0-120 M/min | 0-120 M/min |

| Total power | 17KW (21KW optional) | 17KW (21KW optional) | 17KW (21KW optional) |

| Machine weight | 4800kg | 5800kg | 6100kg |

- Overall size: 5300*5200*1750mm

- Max. Sawing length: 2600mm

- Max. Sawing thickness: 100mm

- Max. Sawing width: 2700mm

- Positioning: Automatic

- Sawing precision : ±0.1mm

- Main saw motor power: 11KW (15KW optional)

- Main saw blade outer dia.: 350-400mm

- Main saw blade inner dia.: 80mm

- Main saw rotation speed: 4100rpm/min

- Scoring saw motor power: 2.2KW

- Scoring saw blade outer dia.: 180mm

- Scoring saw blade inner dia.: 55mm

- Scoring saw rotation speed: 6100rpm/min

- Saw carriage drive motor power: 1.5KW

- Manipulator servo motor power: 1.5KW

- Working air pressure: 0.6-0.8mpa

- Material feeding speed: 0-80 M/min

- Cutting speed: 0-100 M/min

- Backward speed: 0-120 M/min

- Total power: 17KW (21KW optional)

- Machine weight: 4800kg

- Overall size: 5900*5800*1750mm

- Max. Sawing length: 3300mm

- Max. Sawing thickness: 100mm

- Max. Sawing width: 3300mm

- Positioning: Automatic

- Sawing precision: ±0.1mm

- Main saw motor power: 11KW (15KW optional)

- Main saw blade outer dia.: 350-400mm

- Main saw blade inner dia.: 80mm

- Main saw rotation speed: 4100rpm/min

- Scoring saw motor power: 2.2KW

- Scoring saw blade outer dia.: 180mm

- Scoring saw blade inner dia.: 55mm

- Scoring saw rotation speed: 6100rpm/min

- Saw carriage drive motor power: 1.5KW

- Manipulator servo motor power: 1.5KW

- Working air pressure: 0.6-0.8mpa

- Material feeding speed: 0-80 M/min

- Cutting speed: 0-100 M/min

- Backward speed: 0-120 M/min

- Total power: 17KW (21KW optional)

- Machine weight: 5800kg

- Overall size: 6400*6300*1800mm

- Max. Sawing length: 3800mm

- Max. Sawing thickness: 100mm

- Max. Sawing width: 3800mm

- Positioning: Automatic

- Sawing precision: ±0.1mm

- Main saw motor power: 11KW (15KW optional)

- Main saw blade outer dia.: 350-400mm

- Main saw blade inner dia.: 80mm

- Main saw rotation speed: 4100rpm/min

- Scoring saw motor power: 2.2KW

- Scoring saw blade outer dia.: 180mm

- Scoring saw blade inner dia.: 55mm

- Scoring saw rotation speed: 6100rpm/min

- Saw carriage drive motor power: 1.5KW

- Manipulator servo motor power: 1.5KW

- Working air pressure: 0.6-0.8mpa

- Material feeding speed: 0-80 M/min

- Cutting speed: 0-100 M/min

- Backward speed: 0-120 M/min

- Total power: 17KW (21KW optional)

- Machine weight: 6100kg

This horizontal panel saw is a computer controlled panel dividing saw used to cut panels into pieces, it offers high performance in precise cutting and working speed. The cutting speed can reach 40m/min, it makes the computer controlled panel saw suitable for large batch production of furniture. Our CNC panel saw is easily operated in conjunction with a lifting table to load the panel, thus eliminating the need for manual loading and maximizing the productivity of panel cutting.

Integrated mechanical design, motor unit and electronic control are the features that guarantee high productivity, flexibility, high precision cutting and a cutting accuracy up to 0.15mm.

-

-

Control system:

Taiwan Fatke PLC + touch screen

-

-

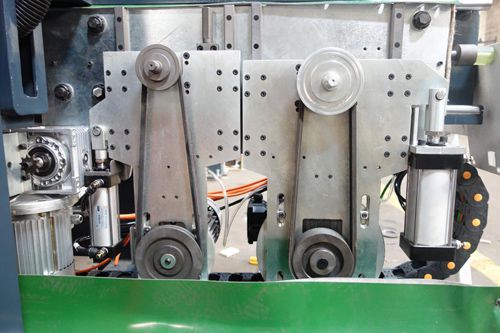

Transmission motor:

INVT servo and inverter (designated brand is acceptable)

-

-

Electrical parts:

Schneider contactors and wires, safe and reliable power supply and long life service.

-

-

Guide rail:

Germany SLM steel belt guide rail, hardening treatment without deformation, high efficiency and dust-proof, stable running with high precision.

-

-

Solenoid valve:

Taiwan Airtec solenoid valve control provides the machine with stable air pressure.

-

-

Cables:

high flexible & tamper-proof, all wires can be identified easily with numbers. And the cables were placed into the drag chain in sequence, easy maintenance.

-

-

Safety devices:

feeding protection, over-travel protection, emergency stop protection, position limitation, air pressure alarm, safety door cover, lubricating system alarm etc.

-

-

Precise cuts

The saw carriage drive is based on German technology. The variable speed of the saw carriage is precisely controlled by perfect co-working of reducer and rack & pinion system to ensure panel feeding cutting accuracy of ±0.15mm. It is possible to realize automatic positioning according to different cutting width.

-

-

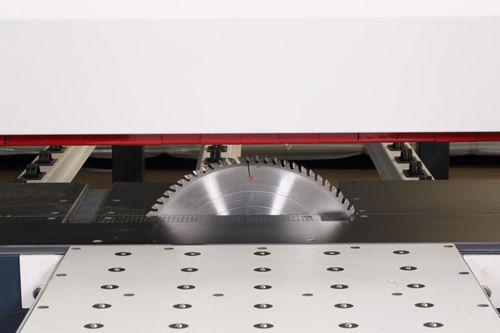

Independent lifting of main saw and scoring saw

The main saw and scoring saw adopt independent lifting control system. The main saw is driven utilizing Igarashi motor of 15KW, while the motor power of scoring saw is 2.2KW. The maximum thickness of panel to be cut is up to 90mm. This guarantees increased cutting speed and reduced load of saw blades, making the blades more durable.

-

-

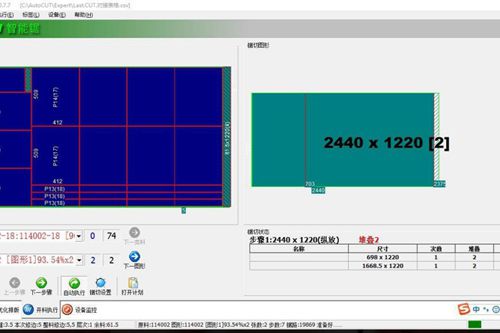

PC control system

The control can manage complex cutting plans, it permits the connection with a variety of cutting software, barcode management software and factory automation software.

-

-

Robust structure

The entire sawing machine is constructed with heavy-duty steel. The pressure bar is durable and non-deformable, it enables the workpieces to be tightly lied on working table. Air floatation table top is configurable to make panel loading and unloading easier and protect panels from being scratched.

-

-

Cutting optimization software (optional)

This programmable software assists in optimizing cutting operations for panel-shaped materials. It can greatly increase processing accuracy and reducing cutting errors. The high-definition 19" touch screen supports better visual effects, guaranteeing a smooth operation. Compatible with a variety of cutting software and factory automation software, it can realize optimal material administration and improved material utilization rate.