CNC Side Hole Drilling Machine

Drilling effects

Technical Data

| Model | |

|

| Max. working length | 2400mm | 2400mm |

| Working station | 3 | 3 |

| Spindle quantity | 1pcs | 2pcs |

| Spindle power | 2.2kw | 2.2kw |

| Spindle speed | 24000rpm/min | 24000rpm/min |

| Rapid speed | 150m/min | 150m/min |

| Working speed | 105m/min | 105m/min |

| Total power | 4kw | 4kw |

| Overall dimension | 3320*1770*1550mm | 3320*1770*1550mm |

| Weight | 230kg | 300kg |

- Max. Working length: 2400mm

- Working station: 3

- Spindle quantity: 1pcs

- Spindle power: 2.2kw

- Spindle speed: 24000rpm/min

- Rapid speed: 150m/min

- Working speed: 105m/min

- Total power: 4kw

- Overall dimension: 3320*1770*1550mm

- Weight: 230kg

- Max. Working length: 2400mm

- Working station: 3

- Spindle quantity: 2pcs

- Spindle power: 2.2kw

- Spindle speed: 24000rpm/min

- Rapid speed: 150m/min

- Working speed: 105m/min

- Total power: 4kw

- Overall dimension: 3320*1770*1550mm

- Weight: 300kg

-

SKD-1

SKD-1

-

SKD-2

SKD-2

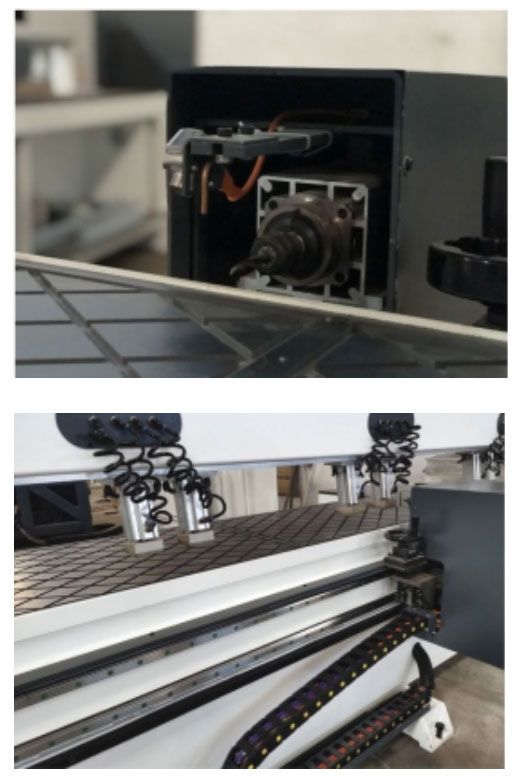

Automatic side hole drilling machine is suitable for furniture panel processing. It is an ideal woodworking machine to replace the conventional drilling machine, eliminating the dependence on skilled workers. Coupled with professional design software, the drilling machine can be easily operated, greatly improving drilling efficiency while reducing the labor cost.

Features

- This machine is designed for drilling side holes for panel furniture, featuring simple operation, allowing operator to use it after short time training;

- Infrared scanning, precise and fast data input, rapid positioning of sheet material, compatible with all kinds of furniture design software;

- Robust welded structure with high quality components, including Taiwan Xinyue rack and pinion, Taiwan CSK rail, Taiwan planetary reducer;

- Independent computer control, easy operation and simple maintenance;

- Three working sections can simultaneously process three panels of different sizes, providing high efficiency;

- Automatic lubrication system prolongs the service life of the machine;

Applications

- Furniture: cabinets, panel, office furniture, chairs, doors and windows;

- Wood products: speakers, game cabinets, computer desks, sewing machines, musical instruments;

- Decoration: acrylic, PVC, MDF, artificial stone, glass, plastic, copper, aluminum and other soft metal sheet;

Since 2003, ANNT has been providing woodworking machines to meet our customer's wood and lumber processing needs. The company has always had a strong commitment to the woodworking manufacturing industry. We know that all furniture manufacturers, wood fabricators or any wood and lumber processing companies want to make use of leading woodworking tools, we continuously strive to manufacture the high quality wood processing machinery, helping our customers stay ahead in their competitive market. Every woodworking machine such as edge banding machine or table saw we provide is custom manufactured precisely to meet customer’s needs. When you are looking for a wood processing machine that allows you to manufacture high accuracy products, our CNC machining centers can provide you with exactly what you require in an efficient manner. Please feel free to contact us to discuss your requirements of panel saw or edge bander and we'll be delighted to offer our premium quality woodworking machines.

Other Products