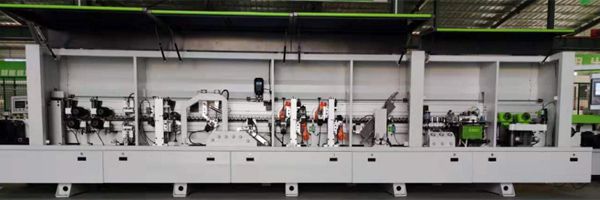

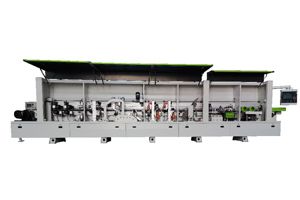

Edge Banding Machine, HKJ-368EQS

| Total power | 23.3KW |

| Dimension (L*W*H) | 7230*900*1700mm |

| Feed speed | 15-23m/min |

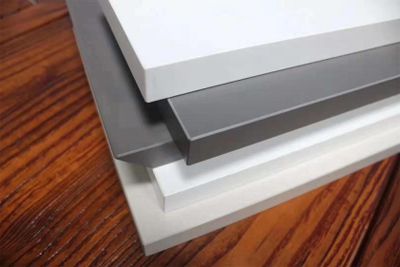

| Edge thickness | 0.4-3mm |

| Panel thickness | 10-60mm |

| Panel length | ≥120mm |

| Panel width | ≥95mm |

| Working pressure | 0.6Mpa |

| Min. panel size (L*W) | 120*95mm |

| Weight | 2300kg |

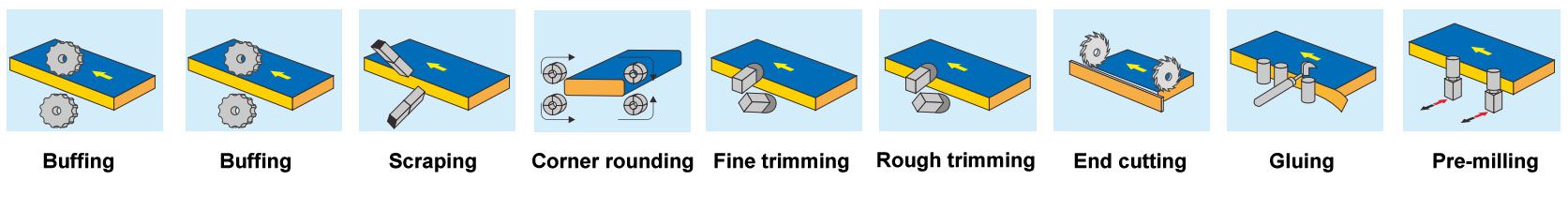

This type of edge banding machine is perfect for processing a variety of wood panels. It is fully configured with functions of separating, pre-milling, gluing, banding, end cutting, rough trimming, fine trimming, corner rounding, scraping, double buffing, cleaning, pneumatic blade adjustment, electric lifting and automatic lubrication.

The pneumatic blade adjustment function allows flexible changing of edging strip thickness, eliminating the need for manual adjustment. The separating cleaning function assists in providing better edge banding result. And the automatic lubrication system ensures longer service life of the machine.

The edge bander machine is applicable to straight line edging and trimming for MDF, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

-

-

After manually placing the panel on the conveyor belt, this edgebander will automatically complete the entire edge banding process.

-

-

Automatic lubrication system circulates lubrication for smooth operation and prolonged service life of parts.

-

-

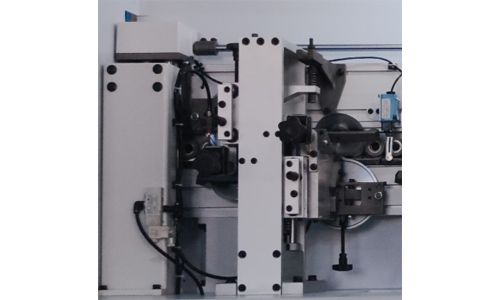

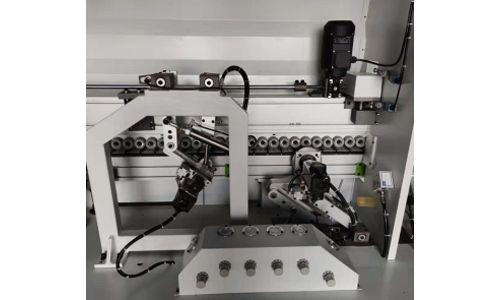

Dual-head pre-milling unit efficiently ensures burr-free and smooth cuts, resulting a perfect preparation for workpiece edge gluing.

-

-

Gluing unit is equipped for evenly applying hot melt glue on workpiece edges, it provides an excellent adhesion.

-

-

Rough trimming & fine trimming units perfectly remove upper and lower overhanging edges to give a smooth looking edging.

-

-

Corner rounding system guarantees that edging strip moves flexibly along the curved edge of workpiece during conveying process, providing accurate contour-tracing control to ensure optimal finish quality.