Edge Banding Machine, HKJ-368B

| Total power | 9.3KW |

| Dimension (L*W*H) | 4100*900*1560mm |

| Feed speed | 18-22m/min |

| Edge thickness | 0.4-3mm |

| Panel thickness | 10-60mm |

| Panel length | ≥120mm |

| Panel width | ≥60mm |

| Working pressure | 0.6Mpa |

| Min. panel size (L*W) | 300*60mm |

| Weight | 1500kg |

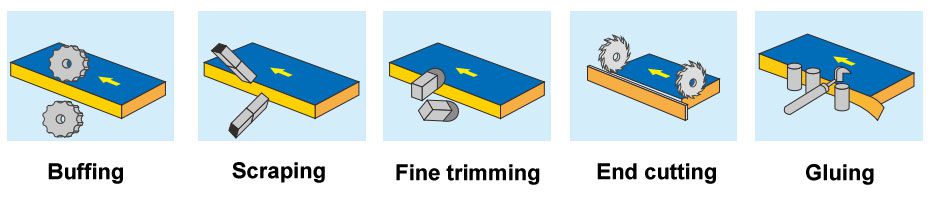

This series edge banding machine ensures superior finish for a wide range of panel materials including MDF, solid wood board, particleboard, plywood, etc., with feed speed of 18-22m/min. The basic configurations include gluing unit, end cutting unit, fine trimming unit, scraper unit and buffing unit, can solve your specific needs for wood panel edge banding. The edge bander is featured by easy maintenance, stable operation and high durability. The automatic lubrication system provides long service life of machine.

-

-

After manually placing the panel on the conveyor belt, this edgebander will automatically complete the entire edge banding process.

-

-

Automatic lubrication system circulates lubrication for smooth operation and prolonged service life of parts.