High-speed Edge Banding Machine, HKJ-668QP

| Total power | 11KW |

| Dimension (L*W*H) | 5000*900*1560mm |

| Feed speed | 18-25m/min |

| Edge thickness | 0.4-3mm |

| Panel thickness | 10-60mm |

| Panel length | ≥120mm |

| Panel width | ≥60mm |

| Working pressure | 0.6Mpa |

| Min. panel size (L*W) | 300*60mm |

| Weight | 1700kg |

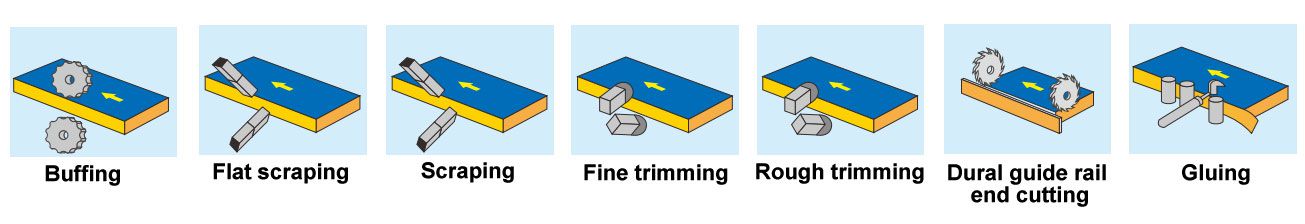

Our high-speed edge banding machine ensures feed speed of 20-25m/min, it is configured with gluing unit, quick end trimming unit, rough trimming, fine trimming, scraper unit, flat scraper unit, buffing unit, pneumatic blade adjustment system, electric lifting system and automatic lubrication system. With features of fast processing speed, high work efficiency, easy operation, this edgebander machine can solve your basic needs of edging and trimming for MDF, blockboard, solid wood board, polymer door panel, plywood, etc.

-

-

After manually placing the panel on the conveyor belt, this edgebander will automatically complete the entire edge banding process.

-

-

Automatic lubrication system circulates lubrication for smooth operation and prolonged service life of parts.

-

-

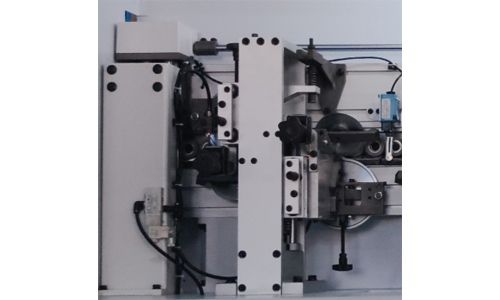

Gluing unit is equipped for evenly applying hot melt glue on workpiece edges, it provides an excellent adhesion.

-

-

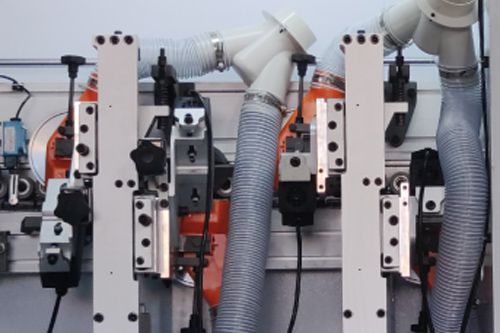

Dual linear guide way end trimming unit rapidly removes exceeding edging tape from the front and rear of the panel.

-

-

Rough trimming & fine trimming units perfectly remove upper and lower overhanging edges to give a smooth looking edging.