Membrane Press Machine, M3150D M2480D

Samples

Technical Data

| Model | | |

| Control mode | PLC | PLC |

| Negative pressure | 95kpa | 95kpa |

| Processing size | 2530 X 1230 X 60mm | 2500 X 1100 X 50mm |

| Total power | 27kw | 15kw |

| Overall size | 9600*1800*1800mm | 9600*1800*1800mm |

| Weight | 2000kg | 1800kg |

- Control mode: PLC

- Negative pressure: 95kpa

- Processing size: 2530 X 1230 X 60mm

- Total power: 27kw

- Overall size: 9600*1800*1800mm

- Weight: 2000kg

- Control mode: PLC

- Negative pressure: 95kpa

- Processing size: 2500 X 1100 X 50mm

- Total power: 15kw

- Overall size: 9600*1800*1800mm

- Weight: 1800kg

This membrane press machine is designed for woodworking and furniture production to press coating materials such as wood veneer and PVC foil onto base panels which are embossed with specific patterns. The membrane vacuum press is also perfect for pressing veneer onto curved surface of solid wood panel, providing an improved realistic aesthetic with 3D effect. We can get your membrane press custom manufactured according to your specific requirements.

Features

- The far infrared radiant heating panel features fast heating speed, strong penetrating power, energy saving and environmental protection.

- The thickened high-density insulation board is 360 degree fully sealed to further improve energy-saving effect.

- Independent multi-zone heating control, can be separately adjusted to ensure even temperature balance.

- Adopts American solid-state module for heating with PID control, temperature difference is controlled within 1 degree, and the precision is 10 times of the ordinary control mode.

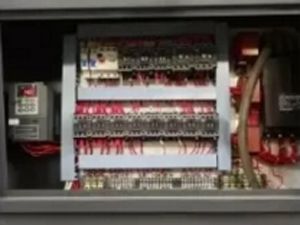

- The circuit is controlled by PLC, which is fast and stable with low failure rate.

- Man-machine interface operation, double-worktable, with the memory of 24 different PVC, can meet the requirements for different thickness of PVC, quick switch by one button.

- High-power cooling fan to quickly cool the workpiece and improve the work efficiency.

- Integrated air circuit unit for easy maintenance and easy adjustment.

- Fully sealed circuit control cabinet, high level dustproof and moisture proof, prolong the service life of all electrical devices.

- High-current terminals are treated with tin-lining to further improve the stability of the circuit.

- The worktable adopts shaft direct drive, and feeding speed is controlled by inverter, enabling the material to be rapidly moved into the working area, thus greatly reducing the temperature difference between front and back worktable.

- Imported original rubber wheel is used as worktable transport wheel, which is silent and has a long service life.

- The pressure frame is made of aluminum alloy which minimizes the affects to the temperature of the worktable.

- The pressure frame uses pneumatic clamps for quick operation, ensuring labor saving.

Since 2003, ANNT has been providing woodworking machines to meet our customer's wood and lumber processing needs. The company has always had a strong commitment to the woodworking manufacturing industry. We know that all furniture manufacturers, wood fabricators or any wood and lumber processing companies want to make use of leading woodworking tools, we continuously strive to manufacture the high quality wood processing machinery, helping our customers stay ahead in their competitive market. Every woodworking machine such as edge banding machine or table saw we provide is custom manufactured precisely to meet customer’s needs. When you are looking for a wood processing machine that allows you to manufacture high accuracy products, our CNC machining centers can provide you with exactly what you require in an efficient manner. Please feel free to contact us to discuss your requirements of panel saw or edge bander and we'll be delighted to offer our premium quality woodworking machines.

Other Products