Edge Banding Machine, HKJ-368AH

| Total power | 12.5KW |

| Dimension (L*W*H) | 5760*900*1700mm |

| Feed speed | 18-22m/min |

| Edge thickness | 0.4-3mm |

| Panel thickness | 10-60mm |

| Panel length | ≥120mm |

| Panel width | ≥30mm |

| Working pressure | 0.6Mpa |

| Min. panel size (L*W) | 300*60mm |

| Weight | 1700kg |

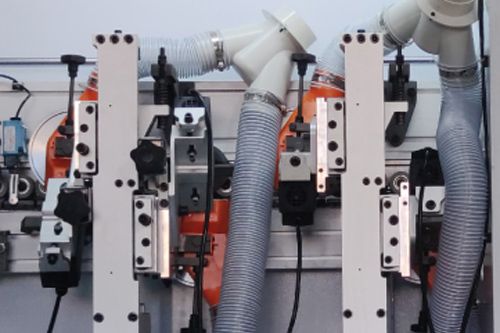

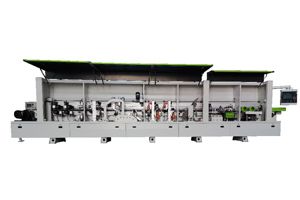

This series edge banding machine is suitable for straight line edging and trimming of MDF, solid wood board, particleboard, plywood, etc., and designed with feed speed of 18-22m/min. The edge bander is offered with dual-color gluing unit, allowing quick changeover between two different glue colors for higher work efficiency. Combined with functions of end cutting, rough trimming, fine trimming, scraping and buffing, this edge bander machine can satisfy your basic needs for wood panel edge banding. In addition, independently operated control panel makes machine operation and maintenance easier, and the automatic lubrication system can prolong the service life of this machine.

-

-

After manually placing the panel on the conveyor belt, this machine will automatically complete the entire edge banding process.

-

-

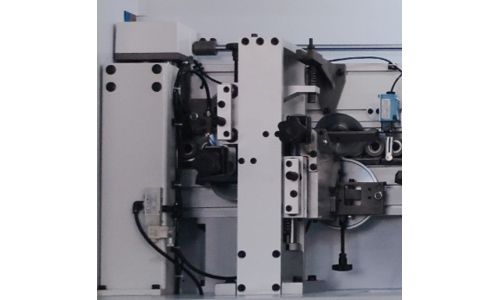

Automatic lubrication system circulates lubrication for smooth operation and prolonged service life of parts.