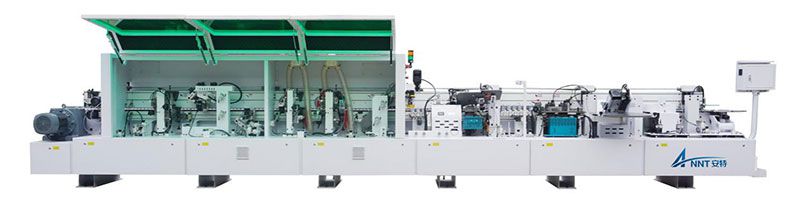

Edge Banding Machine (Bevel/Straight Edge), HKJ-633DJ

| Model | HKJ-633DJ | Bevel angle | 45° (non-adjustable) |

| Panel width | ≥120mm | Feed speed (bevel edge panel) | 13m/min |

| Panel length | ≥200mm | Feed speed (straight edge panel) | 13-20m/min |

| Bevel edge panel thickness | 12-25mm | Power | 27kw |

| Straight edge panel thickness | 9-43mm | Dimension | 9600*900*1750mm |

| Edge tape thickness | 0.8-2.0mm | Air pressure | 0.65Mpa |

| Voltage | 380/220v 50Hz | Weight | 4200kg |

The edge banding machine is suitable for handling bevel edges of door panel, drawer panel, office table panel, etc.

-

-

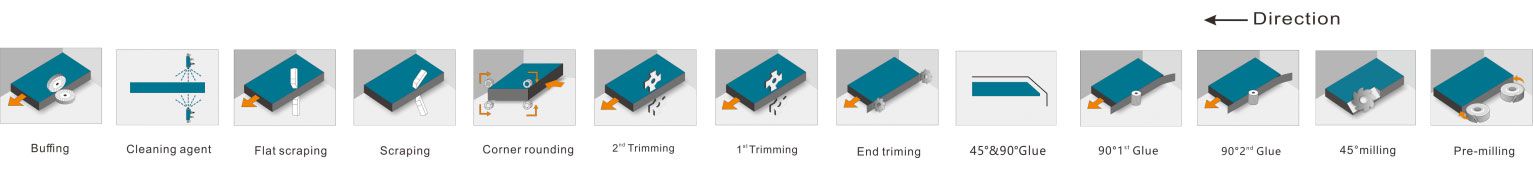

One-key switch

Achieving one-key switching between bevel edge and straight edge

-

-

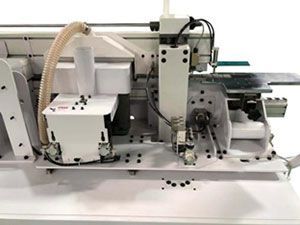

45 degree milling unit

Multiple saw blades for milling of angled edge up to 45degree, the milling unit is equipped with dust collection unit to efficiently remove dust.

-

-

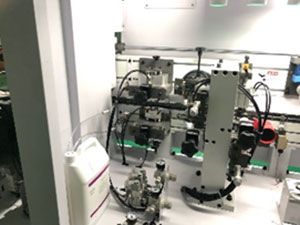

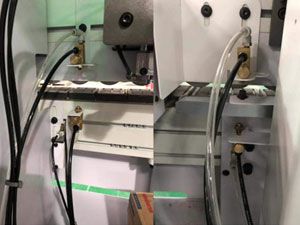

Gluing unit

Simultaneously applying glue to the bevel and straight panel edges, tapes are pressed onto bevel and straight panel edges by pneumatic pressure rollers at two sides.

-

-

Pre-milling unit

Simultaneous adjustment for pre-milling, ensuring accurate pre-milling of both bevel edge and straight edge.

-

-

Edge tape grooving unit

Equipped with pneumatic pressure pad, this unit grooves the edge tape back for better edge banding effect, the height and depth of groove position are adjustable.

-

-

Trimming unit

The trimming unit is equipped with 0.9KW high power high frequency motor and diamond cutters, ensuring effortless trimming and low noise level.

-

-

Corner rounding unit

The corner rounding function enables edge banding effect more attractive.

-

-

Scraping unit

Specially designed for bevel edge, the scraping unit delivers precision finishing for the appearance of panels.

-

-

Pneumatic parts

Key parts are all imported to ensure fast and stable operation.

-

-

Heating unit

The heating unit softens the edge tape while provides secondary heating for high gluing performance.

-

-

Cleaning unit

Cleaning unit with automatic nozzle adjustment keeps straight or bevel edges clean, eliminating the need for manual adjustment.